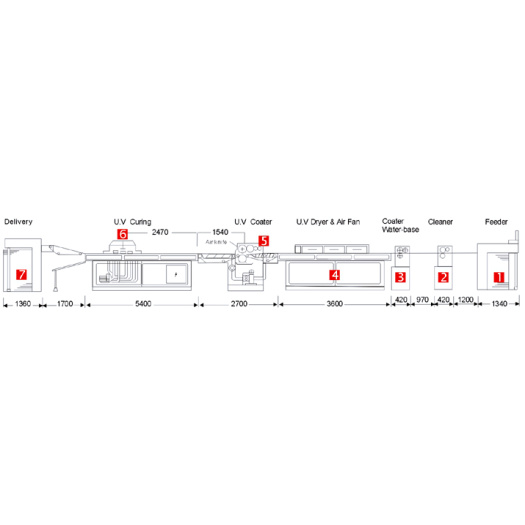

1.STREAM FEEDER

- Suction head with vacuum pump suction system requires no lubricant or oil.

- The feeder can be adjusted while running.

- Double sheet detector.

2.SHEET CLEANING UNIT

- press the paper even.

- Remove the remaining dust after printing.

- dusting function, add to the evenness and smoothness after the paper is glazed.

3.BASE COATING UNIT

- smear the foundation oil, to fill up the capillary function of the paper surface

- add the adhesiveness force between UV layer and the oily ink

- reduce the penetration of UV coatings, to keep the paper white

- saves the precious UV oil consumption

4.I.R. DRYING CONVEYOR

- Infrared drying equipment

- Cooling fan system

- Fit for drying job after the smearing of water or soluble

5.UV COATING UNIT

- UV COATING UNIT, equipped with high sensitivity wind-knife system , suitable for glazing of thick and thin paper.

- micro-adjustment for even smearing and control of material usage, makes the paper smooth and glossy.

6.UV DRYING UNIT

- UV radiation makes the UV oil harden and become resistant to wear, and promote the glossiness of the paper surface.

-Equipment with fast cooling equipment , avoids paper curling.

7.AUTOMATIC DELIVERY UNIT

- Conveyor belt produces low noise and make delivery smooth with its upper and lower pressing track design.

-

Smearing on thin paper tends to produce curling, yet the pneumatic

sheet jogging device knocking up both sides of sheet and keep the paper

stable.

Performance And Characteristics:

This machine is a kind of high- and new- tech product integrating

light, machinery and electricity with pneumatic which can be used for

both thick and thin paper, realizes whole-course automation and adopts

belt conveying with high speed and high efficiency. The mechanical

speed adopts variable frequency step less speed regulation and max.

speed is 80m/min. This machine has independent space for every working

station and it can be assemble bases the client request , so it is

suitable for bing used in large printing enterprise.

Main Technical Parameter:

Model:ZXUV-1400

Roller`s Length:1300mm

Paper Size: >127g/m2

Max. Working Speed: 75m/min

Infrared Heating Power: 1.0kw×18

Coating Power: 1.5kw×2

Infrared Power: 4kw

Ultraviolet Power: 8kw×3

Weight: 5500kg

Overall Dimensions(L×W×H): 13140×2100×1700mm

.png) Contact Now

Contact Now