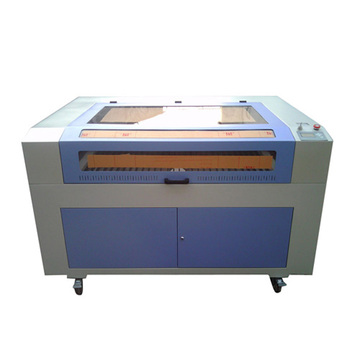

Laser engraving function to improve the efficiency of the sculpture, carved in the surface of the smooth, rounded, reduced rapidly carved non-metallic materials to reduce temperature, carved the deformation and internal force; can be widely used in the field of fine carving of various nonmetal materials.

Laser engraving machine can be divided into: metal laser engraving machine and metal laser engraving machine.

With the complexity of strengthening cutting and carving process, restricting the traditional manual processing and mechanical processing equipment and the technology, is affecting the quality of the product processing object is low accuracy to a certain extent, what is more effect to economic benefits.

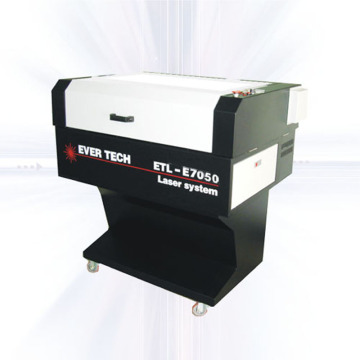

According to the characteristics of laser energy, high density and strong operability, a new generation of XP system high-speed laser cutting and engraving machine has been successfully developed on the basis of many years' production of laser equipment. The equipment has a wide range of material processing, cutting edge smooth, burr free, no polishing, no noise, dust free, fast processing, high precision, less waste, high efficiency, is the best choice for all industries and upgrading.

Contact Now

Contact Now