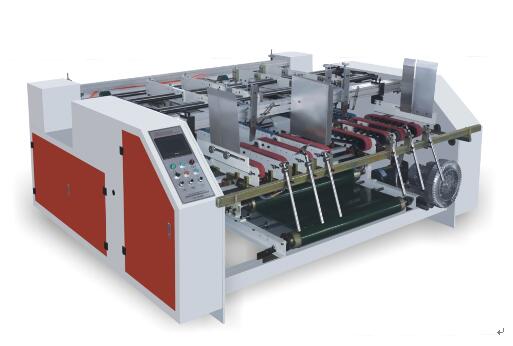

Product Description

Machine overview:

Semi-automatic corrugated box

gluing machine is the most advanced equipment to fill the domestic

manufacturers of corrugated box labor costs rising trend, the equipment has

high efficiency, flexible operation, low maintenance costs, production

efficiency and the traditional manual increase more than ten times. The

advantages of this device is automatic feeding, dispensing, bonding. To meet

the variety, mass production requirements, to adapt to food, cotton and other

product packaging needs, is the ideal carton equipment, corrugated box

industry, is the essential equipment for this scope.

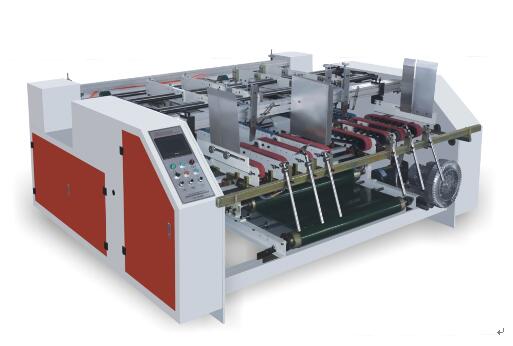

Features:

This series of products made

of mechanical plate, all using a large processing center to complete a

processing to ensure the accuracy of the various stations to ensure that the

equipment is more stable operation.

1. Feeding section: friction feeder, equipped

with two separate motor independent drive, side panel width can be fine-tuned,

with 3 adjustable Feeding knife and 3 small Feeding knife, there are 8 rubber

tape which contains 4 suction belt, two separate control, retractable rear support

can be used for longer box type, to ensure smooth paper delivery fast.

2. Glue part: to match the glue itself, the

use of three groups of plastic system to ensure that the finished product

qualified rate of 100%, double-slot flow of plastic road, to ensure the loss of

glue invalid, improve costs, easy to disassemble, easy to clean.

3. Conveying part: Using of whole process

close to the synchronization technology to ensure that the paper in the fast

transport process does not run away.

4. Paper part: the use of photoelectric

automatic sensor system, high sensitivity, to ensure that the machine speed

block.

5. Pressed part: the use of servo motor and photoelectric

automatic sensor system to ensure consistency and smooth.

6. Operating system: the human touch screen

for the operation center and PLC connection will be warning, detection of

fault, abnormal conditions and operating speed and other information displayed

on the screen, at a glance, and can detect maintenance, work records, online

real-time view of timely processing, truly reflect the efficiency.

7. Electrical system: the use of well-known

brands at home and abroad, in accordance with the European CE standard design,

careful manufacturing, to ensure that the whole stable, high efficiency, low

failure.

8. Transport system: After worker folding the

boards, put it on the transport belt.

The pressing bed will press the product so

that the glue will be sticked well.

.png) Contact Now

Contact Now