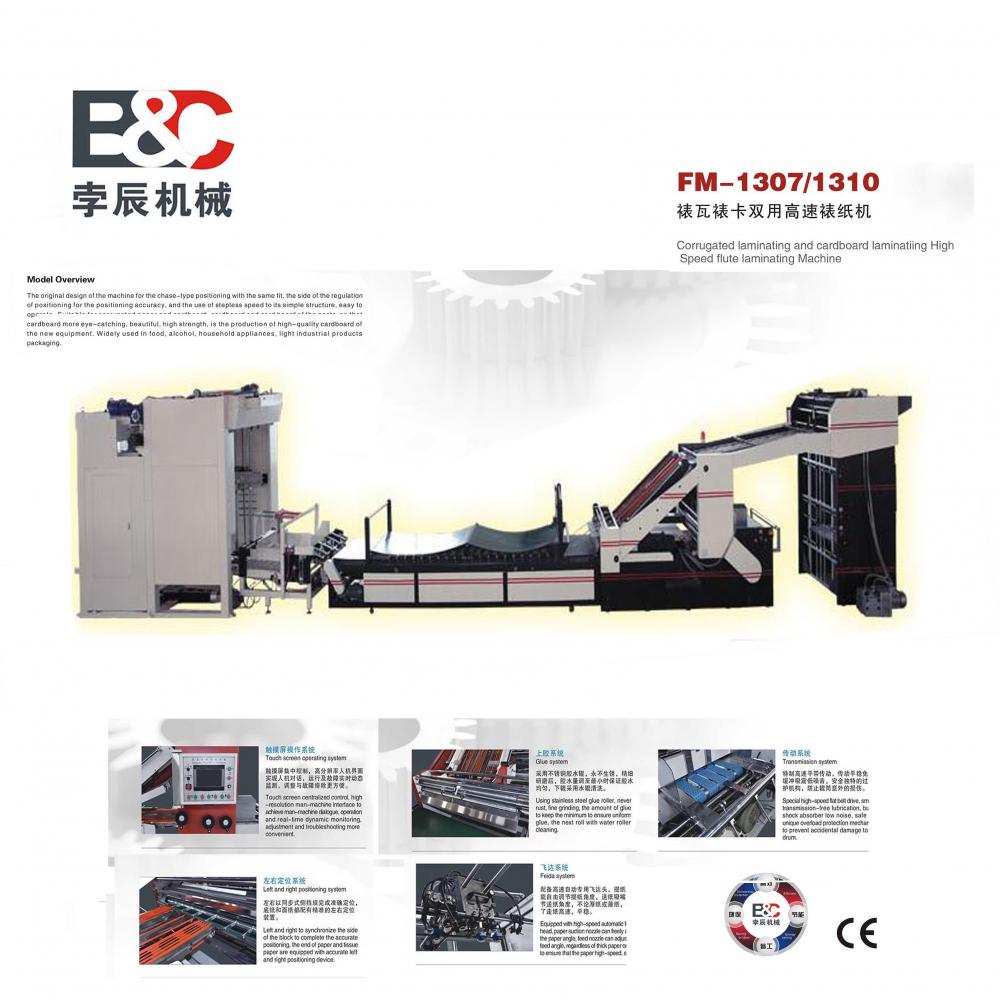

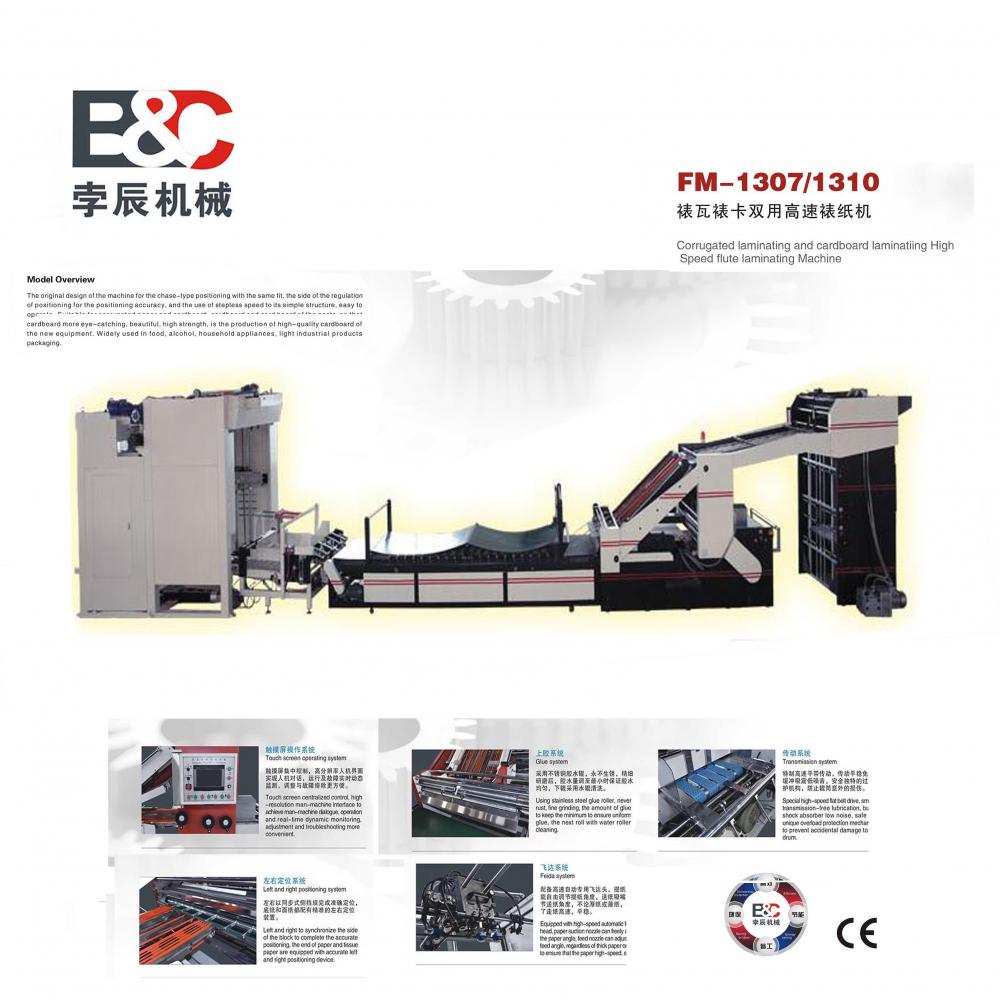

Product Description

Flute Laminating machine/flute laminator machine/ laminating machine

High speed : 12000PCS/H , multi-purpose

Characteristics:

Two function : Two Paperboard laminating, one paper and one corrugated paper laminating dual purpose machine

1. To achieve high efficient and stable operation, main parts of equipment all imported

2. Top sheet feeding mechanism: equipped with high speed auto dedicated feeder, both paper lifting and feeding nozzle can freely adjust angle to the paper, to ensure that whether thick or thin paper can be delivered rapidly and smoothly

3. Top Sheet lifting table: adopting large ratio of high strength turbine reducer to make sure the instant speed stability

4. Top sheet pilling table: Unique idea E-type with double gaps device design can allow sheet to be pushed directly by hand forklift, shorten paper stacking time and improve the efficiency, and also can be installed the orbit type auxiliary pile board

5. Bottom paper drive: Use imported Servo motor electric controlling system to guarantee high sensitivity and high speed operation

6. Bottom paper feeding: Patented technology to ensure corrugate and cardboard goes out smoothly and simple operation

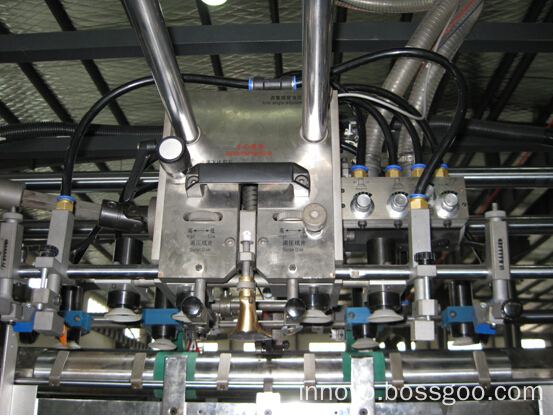

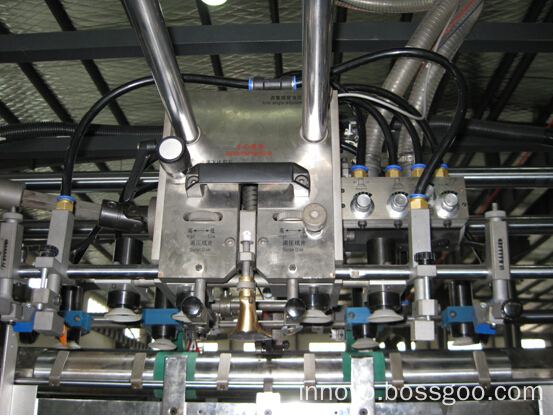

7. Glue roller: Stainless steel roller, never rust, after narrowly grinding, guaranteed the minimum amount glue coated evenly

8. Glue system: Automatic glue complements system, automatic replenishment of losses glue in the process of laminate, and also equipped with glue recycling system

9. Front and back positioning: Unique creation of front gauge positioning system, take advantage of the speed difference of paper feeding and front running, make sure the paper tracking the front gauge and accurately positioning

10. Side positioning: left and right side synchronous block complete the accurate positioning

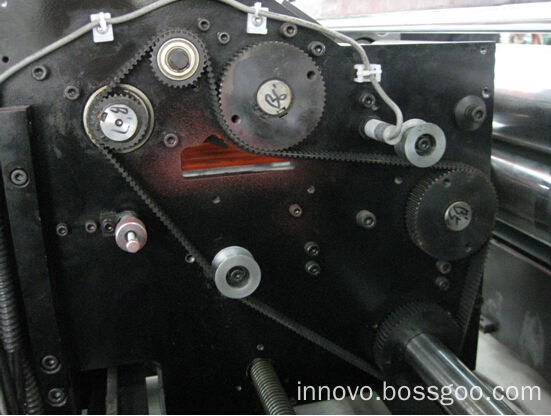

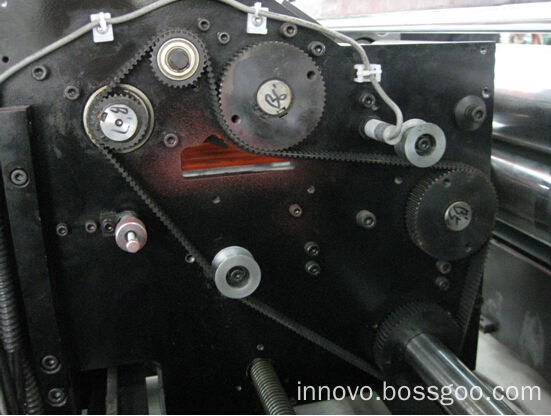

11. Transmission: With imported belt drive, ensure the drive accurate positioning

12. Operating system: Using man-machine interface and PLC combination, display all the information, such as warning, error detect, failures, and operating speed, etc. on the screen at a glance

13. Electrical system: Designed in the accordance with European CE requirement, ensure machine stability, high efficiency and low failure

Parts description:

Top sheet feeding mechanism: equipped with high speed auto dedicated feeder, both paper lifting and feeding nozzle can freely adjust angle to the paper, to ensure that whether thick or thin paper can be delivered rapidly and smoothly.

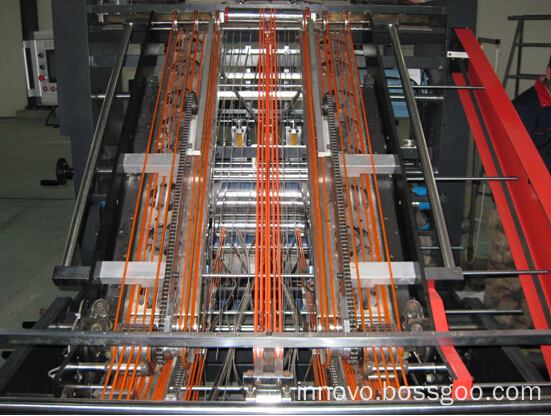

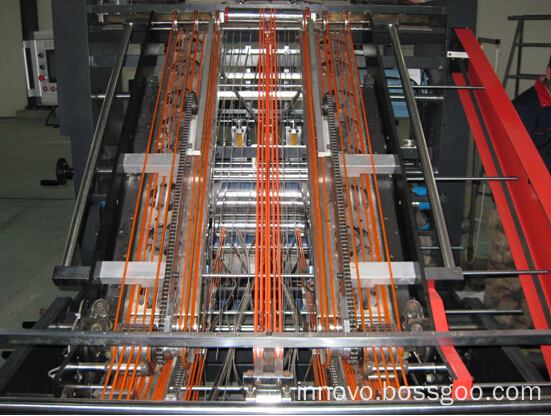

Bottom paper feeding: Use imported Servo motor electric controlling system, with Japan NITTA suction belt to make suction power inverter, and belt cleaned by water roller; patented technology to ensure corrugate and cardboard goes out smoothly and simple operation

Front and back positioning: Paper adsorbed by the fan on the conveyor belt, take advantage of the speed difference of paper feeding and front running, make sure the paper tracking the front gauge and accurately positioning

Side positioning: left and right side synchronous block complete the accurate positioning, both top sheet and bottom paper are equipped with accurate positioning device on left and right.

Glue roller: Stainless steel roller, never rust, after narrowly grinding, guaranteed the minimum amount glue coated evenly. Down roller be cleaned by water roller.

Transmission: With imported double teeth belt drive and Switzerland ROSTA tension device ensure the drive accurate, Stable and low noisy.

Mainframe wallboard are all large-scale machining center once processed, the reasonable design of roller installation position, convenient adjustment and maintenance, the host drive bearings are imported

Electrical system: Designed in the accordance with European CE requirement, ensure machine stability, high efficiency and low failure. Using man-machine interface and PLC combination, display all the information, such as warning, error detect, failures, and operating speed, etc. on the screen at a glance.

Main technical parameters:

|

|

|

Machine Model:

|

FM1307

|

FM1310

|

|

|

|

Maximum paper:

|

Width 1300mm×length 700mm

|

Width 1300mm×length1000mm

|

|

|

|

Minimum paper:

|

Width 500mm×length 300mm

|

Width 500mm×length 300mm

|

|

|

|

Down paper thickness:

|

300g-8mm thickness

|

300g-8mm thickness

|

|

|

|

Surface paper thickness:

|

150g-700g

|

150g-700g

|

|

|

|

Maximum speed:

|

10000 pcs/h

|

7800pcs/h

|

|

|

|

Fitting accuracy:

|

±0.5mm (standard flat paper)

|

|

|

|

Apply glue:

|

resin glue, starch paper jam glue, etc. (PH6-8 use bonding glue)

|

|

|

|

Weight:

|

6500Kg

|

|

|

|

Power supply:

|

380VAC/3P

|

|

|

|

Power:

|

20Kw to work 13Kw

|

|

|

|

Applicable paper:

|

Thin paper, cardboard, coated paper, gray cardboard, thick cardboard, etc.

|

|

|

|

Applicable corrugated:

|

High strength formal single A, B, E, F three, five etc. mounted paper Lenz

|

.png) Contact Now

Contact Now