Product Description

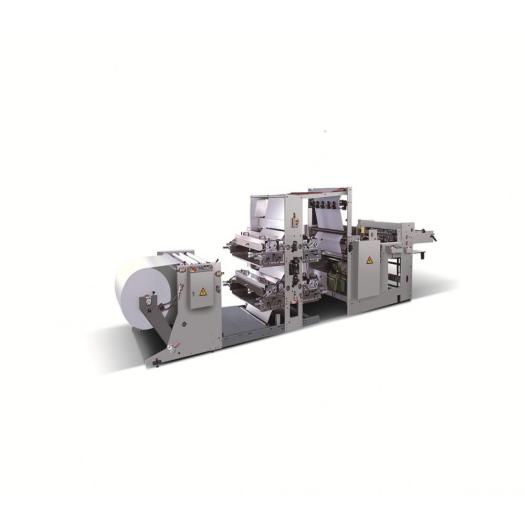

It is a new-generation printer product developed by our company. This machine consists of the electric paper-feeding holder, tension control system, double-sided double-color printing part, transverse cutting part, paper counting and collecting part, paper collecting part, electrical control system and so on. It is an ideal machine to produce various books. The machine will be improved constantly during the manufacturing process, but the changes in the instructions will not be noticed separately.

In order to guarantee correct operation and adjustment, ensure the life safety and machine performance, and extend the service life, one must carefully read this operating manual before starting, operating or adjusting the machine.

1, unwinding device adopts the international popular inflatable shaft packing paper. The tension adopts hydraulic pneumatic brake system. There are no disadvantages such as insensitivity to reaction of phosphorus powder brake, big adjustment and expensive replacement of parts.

2, printing system using German synchronous belt drive, no other company gear transmission caused by noise, gear gap, overprint precision low phenomenon. The eccentric roller adjustment to fine tune printing paper input flexible version of speed, no other company adopts shift teeth to achieve this function, the structure such as easy to rust, the response is not sensitive to damage the bearing, self-locking instability phenomenon. The printing unit and the wallboard cross beam can be locked, no other company product printing roller has serious beating, which leads to the low printing precision, the output can not be improved, and the delivery date can not be completed.

3. The cutting accuracy can be controlled within + 0. 0 2 m. This is the highest accuracy of this kind of machine in china. The cutting paper feeding part adopts Germany Bi Rome emperor device, double head suction paper, effectively avoid domestic paper static electricity, paper difference and so on, can not improve the cutting accuracy, speed and so on. 6 small paper rollers used by the heat treatment process of double external bearing, enhanced performance, high precision roller, beating low; while the other company adopts the seamless steel tube inner hole bearing the outer circle to install wall thickness of only 3mm, the service life is greatly reduced, the phenomenon of poor quality of precision parts.

4, the paper adopts vibration motor vibration paper, so that the paper overlap neatly, you can do 1 meters high paper table, or 1.5 meter paper table.

Spare parts list

Company profile:

We are a professional company which manufactures and sells printing machines and office equipment. Our high quality products and perfect service have enjoyed a high reputation in the industry. Moreover, they sell well all over the world.

Our products include all kinds of offset machines, cutting machines, binding machines, bill printing machines, digital stencil duplicator machines, digital print machines, spray printing machines, print finishing machines and other kinds of printing, packing, advertisement and office equipment.

.png) Contact Now

Contact Now