Product Description

MACHINE FEATURES:

It is elaborated in line with European concepts and up to CE certification in terms of function and safety;

Overall CNC control system guarantees the production can be fulfilled automatically merely by entering all the parameters of box size, clearances of cylinder gaps, axial and circular data of feeder, slotter and die cutter on touch screen featuring accuracy and reliability without any human interference;

Function of order change without machine stop saves the time of plate attachment and preparation to enhance machine efficiency;

Printing plate and inox cylinder doctor blade system are installed on machine unit wall panel, printing unit color change (order change) can be done according to requirements;

PC control system stores production orders and executes auto order change for easy handling;

Pneumatic printing plate positioning system with jumbo gears braking system to ensure the gears correct meshing after order change and reset without machine stop;

Vacuum conveyance, the vacuum chamber elevation is set electrically and digitally at max setting value of 10mm; encoder adjustment, photocell limitation; Japanese precise bearings and lubrication system, precise straight rails position vacuum chamber; three sectional vacuum design to ensure the excellent printing registration accuracy on min 250mm printing length; the fan flow is set with variable frequency change to meet requirements of diversified blanks suction; the total fan power capacity is 3.7x3=11.1Kw;The distance between two adjacent printers is 1,485mm, which is 2.4 times that of normal movable machine units and the prolonged distance will improve ink drying effectively and save heating power. It does not need additional independent heating dryers when test is done on white or kraft corrugated blanks at 220 sheets/min; it dose not need independent dryer (except UV varnishing) when printing, slotting and die-cutting are carried out on coated white corrugated blanks at 150 sheet/min; only the additional independent dryer is needed when machine runs at 150~220 sheets/min.

Vacuum suction flow capacity can be set with frequency conversion to ensure the printing requirements on different blanks, the min blank feeding length is 350mm to guarantee +/-0.3mm accuracy registration; +/-0.25mm overprinting accuracy can be satisfied when the blank length is more than 400mm;

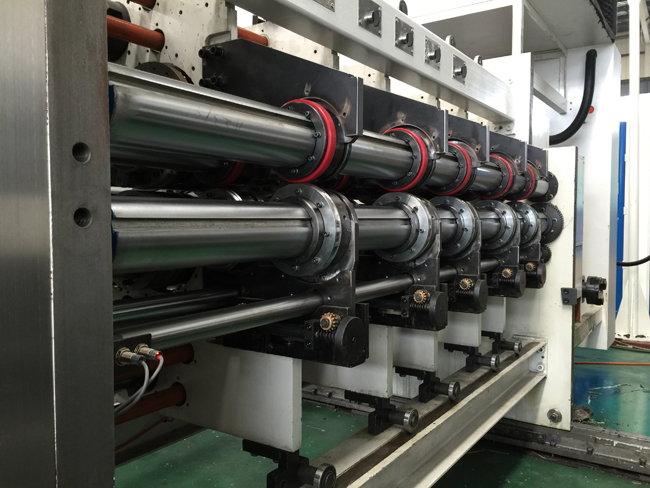

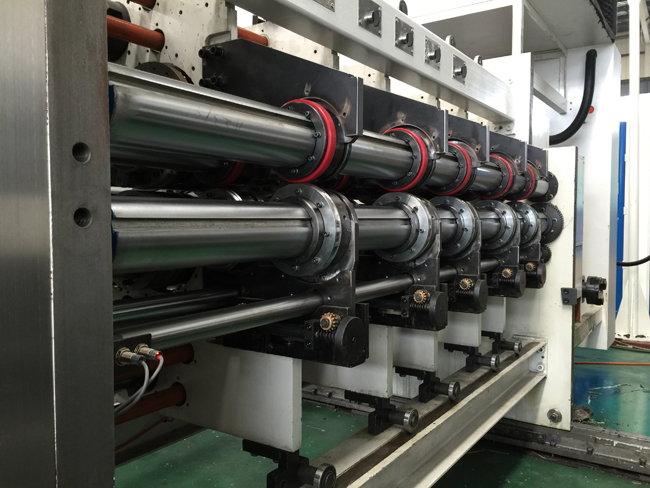

Entire machine is made with quality materials and components, all the transmission rollers are of quality steel through static/dynamic balance tests, polished after chromed;

All gears are made of special steel alloy under hardening and grinding to let them up >60 HR;

All the bearings are purchased from Japan;

All the electric control devices are purchased from Schneider France and others suppliers;.

Feeder

1.Control System

It functions in an entire auto production control, the production can be fulfilled automatically merely by entering all the parameters of box size, clearances of cylinder gaps, axial and circular data of feeder, slotter and diecutter on touch screen featuring accuracy and reliability without any human interference to heighten output;

2. Wheel Type Front Edge Feeder

3. Pulling Rollers

4. Auto Zeroing

waste;

5. Units Releasing and Closing

6. Dusting System

Printer

The distance between two adjacent stationary printer units is 1485mm, which is 2.4 times of the regular units, the prolonged distance is able to improve the ink drying, save power of dryer. Through the tests on coated board and kraft board being printed, slotted and die cut, when machine speed is at 220 pieces/min, it does not need dryer; when machine is printing coated blanks is at 150 pieces/min, it does not need separate dryer (except UV varnisher); it does need separate dryer, when machine speed reaches 150~ 220 pieces/min;

Slotter

1. Slotting Phase Setting

2. Slotting Axial Setting

3. Pre-scoring Wheel

4. Scoring Wheel

5. Pulling Roller

Die cutter

1. Die cutter Control Panel

2. Die cutter Cylinder (bottom cylinder) @235X2000

3. Anvil Cylinder (top cylinder)

4. Different Compensation Device

5. AUTO FOLDING GLUING UNIT

1)Ejector

Ejector can be shifted laterally entirely to secure the blanks dropped at the center of machine

2)FOLDER

3). Glue Spraying System

4)Power Equipment

5). Feeder

Front edge feeder of vacuum suction is suitable for feeding at high speed;

Precise feeding, even the warp or fine-flute corrugated boards

6.OTHERS

1. Main Motor

Main motor is installed with a frequency inverter of 45kw

2.Bearings

They are all bearings made in Japan.

3.Electric Components

4. Main Transmission Gears

5. Spline Free Joint Ring

Shaft and gear are coupled with spline free joint ring without clearance even a heavy torque is exerted to make the installation and service more simple and precise transmission longer to guarantee the printing registration.

6. It is made of 60mm gray pig iron through annealing and machined with CNC machining center to make it high in accuracy and good in quality.

7.CENTRAL DUST COLLECTING PIPING

An auxiliary concentrated dust suction channel and muffler pipe are designed on entire course vacuum system and a dust collecting tank is also installed.

8. OTHER PURCHASED COMPONENTS

|

No.

|

Titles

|

Supplier

|

|

1

|

Wheel front edge feeder

|

Wheel front edge feeder

|

|

2

|

Touch screen

|

PLC.touch screen from Schneider France

|

|

3

|

Frequency inverter

|

Schneider(fan).Inovance(Main motor)

|

|

4

|

Transmission bearing

|

Made in Japan

|

|

5

|

Electrical elements

|

SCHNEIDER and others international famous mark

|

|

6

|

Spline coupler

|

Shanghai

|

|

7

|

Dual way membrane pump

|

USA

|

|

8

|

Inox cylinder

|

Import from Japan

|

SPECIFICATION

|

Model

|

ZXKM2000

|

|

Max.machine speed(Roller Feeder) (Pcs/min)

|

300

|

|

Max. paper feeding size (mm)

|

900x2000

|

|

Min. paper feeding size (mm)

|

280×600

|

|

Skip feeding (mm)

|

1100x2000

|

|

Max. printing area (mm)

|

900x1900

|

|

Printing plate thickness (mm)

|

7.2

|

|

Printing accuracy (mm)

|

± 0.25

|

|

Slotting(Die cutting) accuracy (mm)

|

± 1

|

.png) Contact Now

Contact Now