Product Description

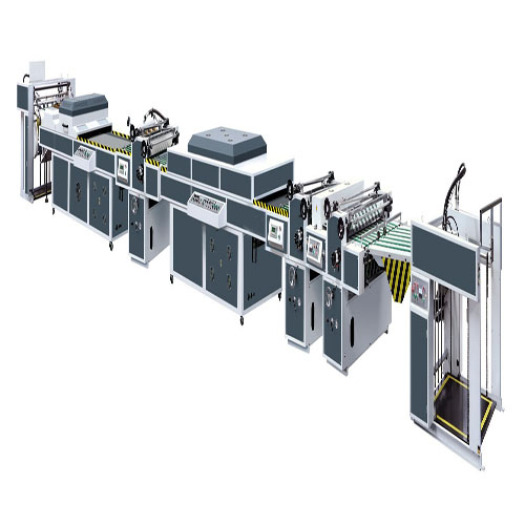

ZXL-1000/1200A automatic full large

thin paper UV roller coating machine

Quick Details

-

Condition: New

-

Type: Other

-

Computerized: Yes

-

Place of Origin: Zhejiang, China (Mainland)

-

Brand Name: innovo

-

Model Number: ZXL-1000/1200A

-

Voltage: 380V

-

Power(W): 89kw

-

paper processing machinery: UV coating machine

Packaging & Delivery

|

Packaging Details:

|

wooden

|

|

Delivery Detail:

|

20 days after payment

|

Specifications

Coating Machine: It is full coating machine UV Coating Machine, Paper

Varnishing Machine, Paper Glazing Machine...

Full Details:

Use:

This machine is necessary to printing

products after fine print. All kinds of paper printed matter treated by this

machine are not only improving the smooth finish of surface ,but also damp

proof ,dustproof, sunroof and wear-resistant of for the surface of printed

matter especially after UV vanish Processing. The effect is comparable to

laminating, calendaring treatment, and no film-dropping, curly and back light

defect.

This machine is a kind of high-tech

product with light, machinery, and electricity with pneumatic which can be both

thick and thin paper, realizes whole-course automation and adopts belt

conveying with high speed and high efficiency. The mechanical speed adopts

variable frequency step less speed regulation and max. Speed is 60 m/min. This

machine has independent space for every working station and it can be assemble

bases the client request, so it is suitable for being used in large printing

enterprise.

Paper Feeder Unit

-Stream Feeder Suction head

with vacuum pump suction system requires no lubricant of oil;

- The feeder can be adjusted

while running;

-Double sheet detector.

2.Sheet Cleaning Unit

Press the paper even Remove the remaining dust after printing

- dusting function, add to the

evenness and smoothness after the paper is glazed

- adopt wet water powder remove,

with two-scraper(Stress cylinder automatic adjustment)

- adopt three rollers powder

remove (pressure roller/ rubber roller/wet-water roller)

all purpose with base coating

3.Base Coating Unit

- smear the foundation oil, to fill up the capillary

function of the paper surface

- add the adhesiveness force

between UV layer and the oily ink

- reduce the penetration of UV

coatings, to keep the paper white;

- saves the precious UV oil

consumption

- Three rollers double pressure

double scrapers, adopt cleaning and coating are synchronized operation

- with import Inverter, automatic

stop for malfunction, three-phase oil pump coating

4.I.R. Drying Unit

-With 15KW (15group) I.R. lamp,

Independent adjust of the speed (Schneider VVVF)

- With Teflon conveyor belt, Automatic corrective adjustment, oven is automatic go

up when the machine stop

- The up-blower heat elimination,

with the even temperature in the Oven

- High-power Down-exhaust fan,

Removal of waste heat

5.UV Coating Unit

-UV Coating Unit UV Coating Unit, equipped with high

sensitivity wind-knife system, suitable for glazing of thick and thin paper;

- Micro-adjustment for even

smearing and control of material usage makes the paper smooth and glossy.

- Three rollers double pressure

double scrapers, with 3KW air compressor (With gas tank), Independent adjust of the speed (Schneider VVVF), Machine-wide linkage, automatically shutdown with

paper crimp.

6.UV Drying Unit

-UV Drying Unit UV radiation makes the UV oil harden

and become resistant to wear, and promote the glossiness of the paper surface;

Equipment with fast cooling equipment, avoids paper curling.

- With Teflon conveyor belt, Automatic corrective adjustment, oven is automatic go

up when the machine stop

- 3 groups 8KW transformer ,3 UV lamps,3 capacitance

- 2 groups of cold air blower, 2 groups of pneumatic suction system, 1team discharge air

7.Automatic Delivery Unit

-Automatic Delivery Unit Conveyor belt produces low

noise and make delivery smooth with its upper and lower pressing track design.

Smearing on thin paper tends to produce curling, yet the pneumatic sheet

jogging device knocking up both sides of sheet and keep the paper stable.

Fitting list

|

Spare parts

|

Brand name

|

|

electrical

|

Schneider

|

|

PLC

|

Siemens

|

|

cylinder

|

Airtac

|

|

conveyor belt

|

Teflon

|

|

UV

|

HEBEI

|

|

IR

|

hongda

|

|

air compressor

|

shanghai jinbao

|

|

motor

|

RENMING

|

|

encoder

|

OMRON

|

|

rubber roll

|

YANHONG

|

|

air knife

|

SHUNDA

|

|

inverter

|

OMRON

|

FEATURE:

This machine is a kind of high-and new-tech product

integrating light, machinery and electricity with pneumatic which can be used

for both thick and thin paper, realizes whole-course automation and adopts belt

conveying with high speed and high efficiency. The mechanical speed adopts

variable frequency step less speed regulation and max. Speed is 80m/min. This

machine has independent space for every working station and it can be assemble

bases the client request, so it is suitable for being used in large printing

enterprise.

1. Stream feeder

Suction with vacuum pump suction system requires no

lubricant or oil .

The feeder can be adjusted while running

Double sheet detector

2. Sheet clearing unit

Press the paper even

Remove the remaining dust after printing

Dusting function add to the evenness and

smoothness after the paper is glazed

3. Base coating unit

Smear the foundation oil, to fill up the capillary

function of the paper surface

Add the adhesiveness force between UV layer and the

oily ink

Reduce the penetration of UV coatings, to keep the

paper white

Save the precious UV oil consumption

4. IR. Drying conveyor

Infrared drying equipment

Cooling fan system

Fit for drying job after the smearing of water or

soluble

5. UV coating unit

UV coating unit, equipped with high sensitivity wind

knife system , suitable for micro adjusting of thick and thin paper

Mic-adjustment for even smearing and control of the material

usage, make the paper smooth and gloss

6. UV drying unit

UV radiation makes the UV oil harden and become

resistant to wear, and promote the glossiness of the paper surface

Equipment with fast cooling equipment, avoids paper

curing

6. Automatic delivery unit

Conveyor belt produces low noise and make delivery

smooth with its upper and lower pressing track design.

Smearing on thin paper tends to produce curing, yet

the pneumatic sheet jogging device knocking up both of sheet and keep the

stage.

|

model

|

Model ZXL-1200AUV

|

Model ZXL-1000AUV

|

|

Max sheet size

|

1000*1200MM

|

800*1000mm

|

|

Min sheet size

|

340*406MM

|

340*406mm

|

|

Max coating width

|

1150MM

|

950mm

|

|

Paper thickness

|

80-600/gm2(equipped with wind-knife)

|

80-600/gm2(equipped with wind-knife)

|

|

Max feeder speed

|

8000sheets/hours 4000sheet/hours for the thin paper

|

8000sheets/hours 4000sheet/hours for the thin paper

|

|

Conveyor speed

|

25~60m/min

|

25~60m/min

|

|

dimension

|

16800*2500*1940mm

|

12250*1960*1600mm

|

|

Total weight

|

10500kg

|

10500kg

|

|

Total power

|

89kw

|

89kw

|

.png) Contact Now

Contact Now